Leina designed the customized a 25 tons heavy-duty rail transfer trolley for Indian customer, and has completed debugging and acceptance work. The heavy-duty rail transfer trolley has customized a special hollow platform and a turntable device that interfaces with other production equipment of the customer. The heavy-duty transit trolley is powered by batteries and can run at full load for 4 hours. It is also equipped with safety devices such as sound and light alarm lights, collision blocks, limit switches, and emergency stop buttons, Stable and safe operation, and is highly efficient.

The customized heavy-duty rail transfer trolley is a versatile solution for material handling applications in various industries. This type of trolley is designed to transport heavy loads across a factory or warehouse floor using a rail system. It is reliable, efficient, and flexible, making it an ideal option for businesses looking to improve their operations.

The customization aspect of this trolley is what sets it apart from standard models. The customized heavy-duty rail transfer trolley can be tailored to meet the specific needs of a business. This can include modifications to the size, weight capacity, and shape of the trolley, as well as features such as safety systems, power options, and more.

One of the primary benefits of a customized heavy-duty rail transfer trolley is its ability to move heavy loads safely and efficiently. With proper customization, these trolleys can be designed to handle loads of various sizes and shapes, making them an ideal solution for businesses with diverse material handling requirements.

Furthermore, the customized heavy-duty rail transfer trolley can improve the efficiency and productivity of a facility. These trolleys can be designed to travel at varying speeds and can be equipped with advanced control systems to help optimize material movement. This can result in faster and more efficient material handling processes, reducing downtime and increasing output.

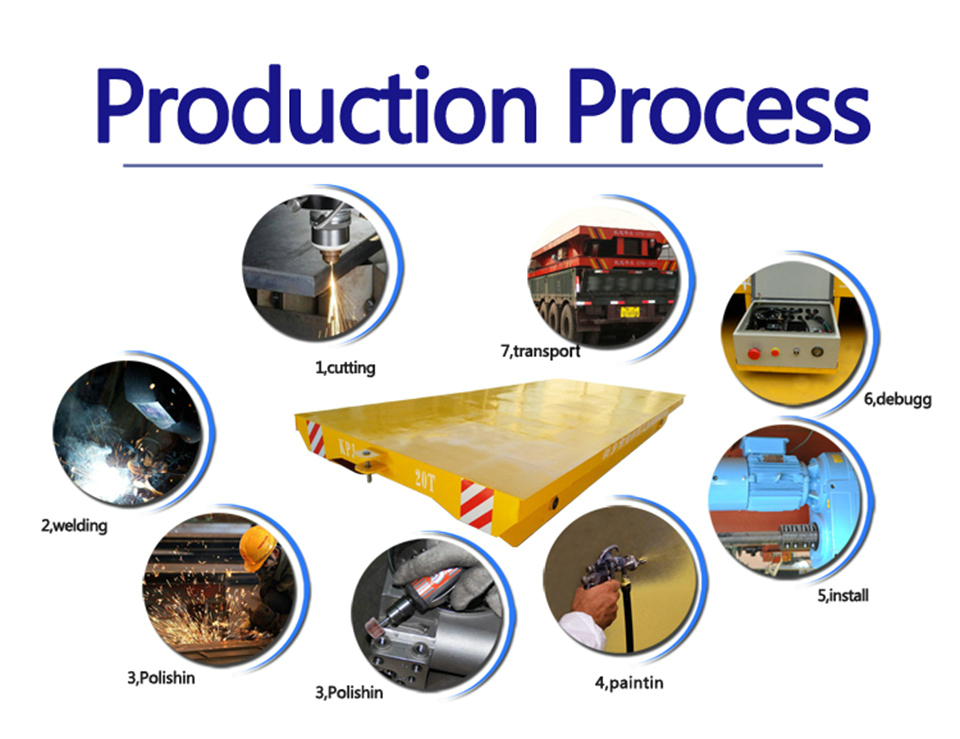

Rail Transfer Trolley Production Process

Design planning: First, design the cart model according to customer needs, including structural layout, performance parameters, etc., and draw detailed drawings.

Raw material procurement: Purchase key components such as high-quality motors, batteries, and frame materials to ensure stable product performance.

Production and processing: Cut and weld the frame, assemble motors, batteries, control systems and other components to form a complete cart structure.

Quality inspection: Perform various performance tests on the assembled trackless transfer vehicle to ensure that the quality meets the standards.

Factory debugging: Final debugging is carried out before leaving the factory to ensure that the vehicle runs smoothly, safely and reliably.

Rail Transfer Trolley Product Parameters

Model: KPX

Load capacity: 20 tons (customizable)

Workbench size: 2500*2000*450 (customizable)

Power supply: maintenance-free battery

Wheels: steel wheels

Continuous working time: 4-6 hours

Control method: wireless remote control/handle

Application: factories, mines, airports, docks, ports, railways

Operation speed: 0-20m/min

Rail Transfer Trolley Manufacturer LEINA

As a professional manufacturer in the handling industry, LEINA has been deeply involved in the field of material transportation for 23 years. With its technical strength and rich industry experience, it has customized efficient and safe transportation solutions for many factories, effectively solving complex transportation problems. Whether it is the handling of precision parts or the smooth transportation of heavy equipment, LEINA can provide customized handling equipment and services.

Rail Transfer Trolley Feature

1. The remote controller has horn , forward , backward , fast forward , rewind , braking , etc .

2. Micro-moving traction and the parking braking function to ensure that the ramp does not slip, and has manual parking brake clutch function.

3. Power emergency stop switch, reasonable installation position, convenient operation and acousto-optic warning. When the vehicle is electrified, the warning lights flicker, warning people in the vicinity to pay attention to safety.

4. Charging wire not less than 15m, with automatic wiring arrangement, retracts.

Why choose us?

· First-class technology

Professional technical team, tailor-made material transportation solutions for you, solve your transportation problems

· Perfect after-sales service

Long warranty period, if there are any use problems during the warranty period, you can contact us at any time.

· Excellent quality

The quality of our company's products strictly complies with industry standards.

· Customer trust

Our company's products have been widely sold to many countries and have won the trust of international partners.

Customer Feedback

The electric transfer vehicles manufactured by LEINA have a diverse and loyal customer base in domestic and international markets. Our products have successfully won the favor and trust of customers around the world, and their strong support is a testament to this.

In terms of customer service, LEINA has demonstrated its unwavering commitment to quality, responsiveness to user needs, honest service, and a customer-first approach. We pride ourselves on serving each of our customers with the utmost dedication, ensuring that their experience with our products and services is unparalleled

FAQ

Q: How long is the warranty period for this cart?

A: Most carts have a warranty period of one year, and some have a warranty period of two years.

Q: What material is the body of this cart made of?

A: The body of this cart is made of high-quality steel, which generally has good corrosion resistance and moisture resistance, and can operate stably in harsh environments.

Q: What is the running speed of this cart?

A: 0-30m/min.

Q: What kind of power supply method does this cart use?

A: This electric transfer cart is battery-powered, and customers can choose maintenance-free lead-acid batteries or lithium batteries according to the actual usage scenario.

Packaging and delivery

Packaging: The entire transfer cart will be packed with tarpaulin. Accessories are transported in wooden boxes. According to the size of the transfer cart, choose a suitable container for transportation. If the size of the transfer cart is relatively large, we can fix the goods on the deck to ensure the safety of transportation. We use wooden boxes to pack the parts of the transfer cart.

Delivery: Manufacturing time, generally 30 days to complete the car manufacturing. The delivery time for non-standard transfer carts is 35-45 days.